Strategic Infrastructure Overview

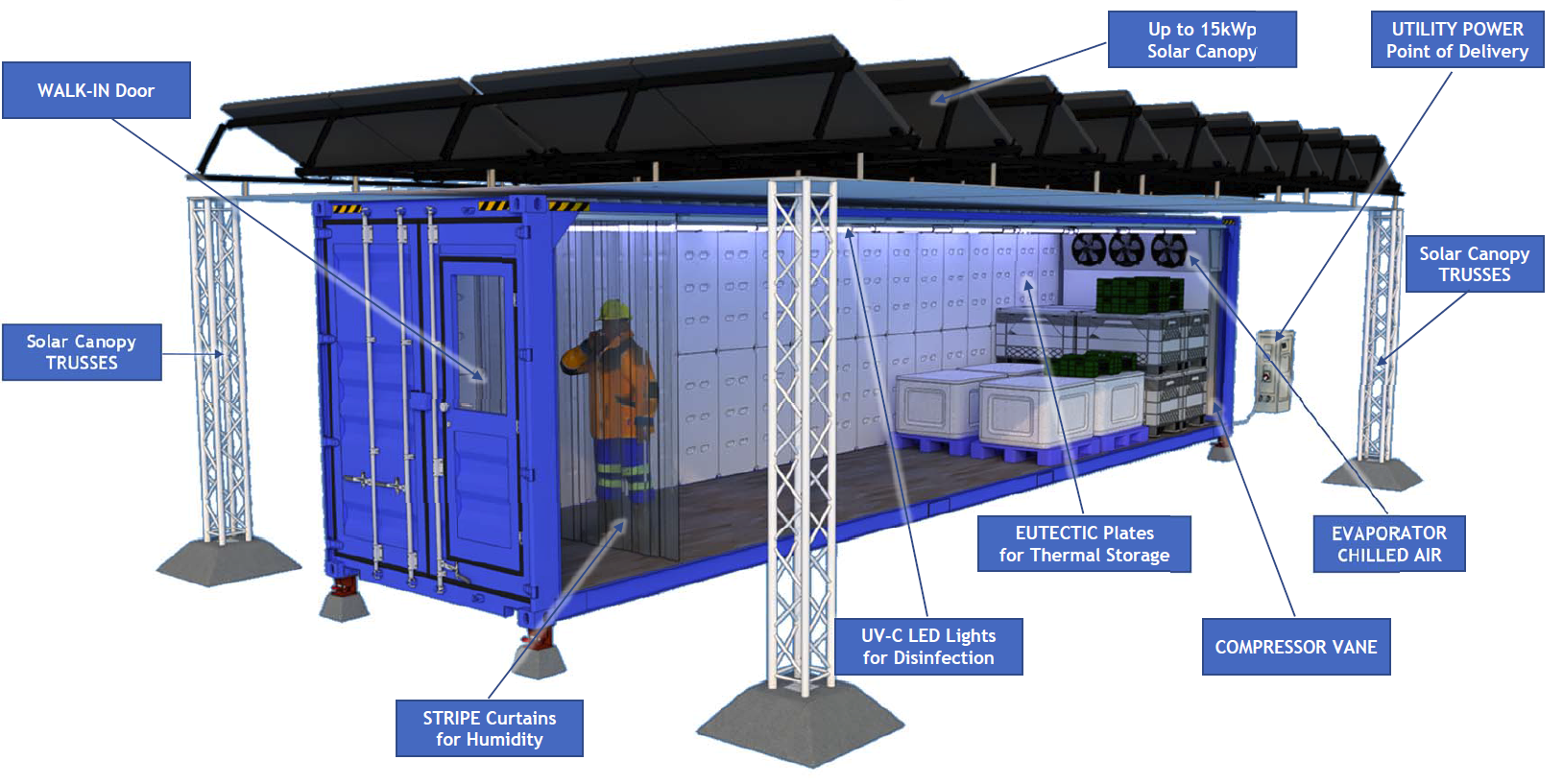

The Indonesian fisheries sector faces a systemic challenge: the disconnect between high-yield remote harvesting grounds and centralized processing hubs. Aerfrigor, in technical collaboration with GEMPACS, has developed a modular cold storage infrastructure specifically engineered to survive and thrive in tropical maritime environments.

Our systems are not merely storage units; they are self-contained thermodynamic nodes. By utilizing advanced refrigeration cycles and energy-independent power sources, we ensure that fishery products (ranging from local skipjack to export-grade yellowfin tuna) maintain their cellular integrity from the moment of catch to the final distribution point. This document outlines the engineering protocols used to achieve stable temperatures as low as -40°C in off-grid and marine environments.

Engineering Standards:

- Thermal Stability: Precision control within ±0.5°C of setpoint.

- Marine Grade: All external components utilize ZMCH coatings and anti-corrosive heat exchangers.

- Export Compliance: Systems factory-tested to meet EU Regulation 853/2004 and FDA HACCP standards.

- Hybrid Power: Automated switching between Solar PV, LiFePO4 Battery, and AC Grid/Generator inputs.

Cold Storage Reefer with Eutectic Plates (PCM) – Click to download Cold Storage Presentation, to know more

The “Cold Battery”: Phase Change Materials (PCM)

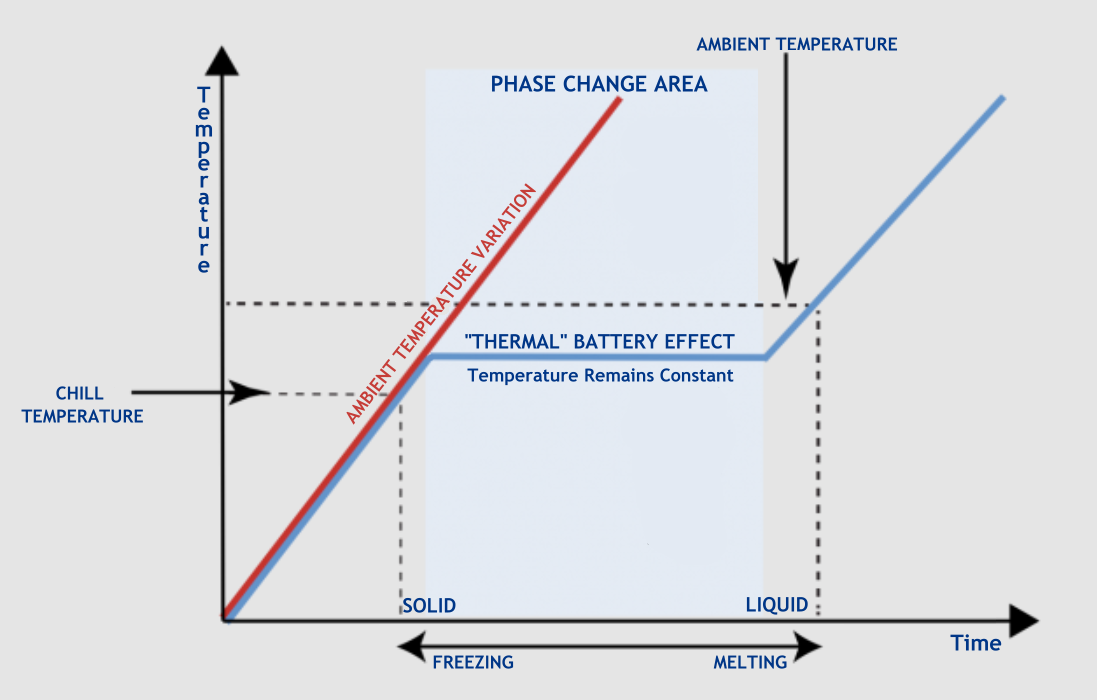

Phase Change Material (PCM) represents the frontier of sustainable refrigeration. Conventional systems store energy in batteries to run compressors; Aerfrigor systems store thermal energy directly within the structure of the cooling unit. This process, detailed on Page 15 of the technical pitch, utilizes the principles of latent heat exchange.

Thermodynamic Principles:

PCMs are substances with a high heat of fusion which, melting and solidifying at a certain temperature, are capable of storing and releasing large amounts of energy. When the GEMPACS solar panels are at peak production (10:00 – 14:00), the cooling system over-performs to “charge” the PCM plates, transitioning the material from a liquid to a solid state. This is known as Latent Heat Storage.

Night-Time Stability

During the night or periods of high cloud cover, the PCM plates begin to melt. As they transition back to a liquid state, they absorb heat from the container’s interior. This “Passive Cooling” phase can maintain -20°C or -40°C temperatures for 8-12 hours without any compressor activity, drastically reducing electricity consumption and mechanical wear.

Peak Shaving & Reliability

In Indonesian island contexts where the grid is unstable, PCM acts as a fail-safe. If a diesel generator fails or the grid goes down, the PCM “Thermal Battery” provides an immediate buffer. This prevents the “Freeze-Thaw” cycles that ruin seafood texture and lead to bacterial growth, ensuring export-quality results every time.

Investment & Equipment Matrix

Prices reflect the modular nature of the system, allowing for the procurement of full containers or standalone cooling machines for existing hulls/structures.

| Reefer Unit Type | Condition | Base MIN (USD) | Base MAX (USD) |

|---|---|---|---|

| 20′ AERFRIGOR Standard | REFURBISHED / NEW | $6,600 / $8,500 | $7,500 / $9,000 |

| 40′ AERFRIGOR Standard | REFURBISHED / NEW | $6,750 / $10,000 | $8,000 / $11,000 |

| 20′ High Cube (HC) | REFURBISHED / NEW | $7,800 / $10,000 | $8,800 / $11,500 |

| 40′ High Cube (HC) | REFURBISHED / NEW | $8,000 / $10,500 | $10,000 / $12,500 |

20′ Cooling (5kW)

STANDALONE UNIT – MACHINE ONLY

40′ Cooling (8kW)

STANDALONE UNIT – MACHINE ONLY

Heavy Duty (10kW)

20’/40′ HIGH CAPACITY MODULE

Multi-Stage Sanitation Science

Seafood safety is determined by microbial load. Aerfrigor’s sanitation module provides a three-tiered defense mechanism to ensure fishery products meet the strictest global import requirements.

This physical process uses short-wavelength ultraviolet (UV-C) light to target the molecular structure of microorganisms. By exposing circulating air to 254nm wavelength irradiation, the system disrupts the DNA and RNA of bacteria, viruses, and mold spores. Because the microbes can no longer reproduce, they are rendered “biologically dead.” This process is continuous and leaves absolutely no chemical residue on the fish.

Ozone is a powerful oxidizing agent. When the container is sealed, the Ozone generator produces O3 gas which permeates every crevice of the cargo and the interior surfaces. It effectively kills surface bacteria and neutralizes odors (such as ammonia buildup from degradation). Post-sanitation, the O3 naturally decomposes back into pure Oxygen (O2), making it the safest gaseous disinfectant for food products.

For the deepest level of sanitation between different harvest batches, the system supports automated chemical fogging. Specialized nozzles spray an ultra-fine mist of approved disinfectants that settle on the floor T-bars and walls, eradicating persistent fungal cultures and biofilm that physical cleaning cannot reach.

On-Board Marine Energy Recovery

Aerfrigor’s marine configuration turns a fishing vessel’s engine room into a power plant for the cold chain. By reclaiming waste energy that is usually vented into the ocean or atmosphere, we achieve ultra-efficient cooling.

Waste Heat Reclaim Streams:

- High-Temp Exhaust: Utilizing high-grade thermal energy from the main engine exhaust to drive absorption chillers.

- Engine Cooling Water: Capturing low-grade heat to stabilize the heat pump cycle.

- Lubricating Oil: Recirculating oil heat through a secondary heat exchanger.

The ZMCH Heat Pump Cycle:

The heart of the marine system is the ZMCH Heat Pump. This unit acts as the “energy traffic controller.” It takes the harvested waste heat and uses it to compress the refrigerant or charge the PCM plates. This setup allows for Blast Freezing (down to -60°C in specialized modules) while the vessel is at sea, ensuring “Frozen-at-Sea” quality that commands premium prices in international markets.

GEMPACS Solar Hybridization

The “GEMPACS Solar Frame” is a revolutionary modular solution for shore-based fishing hubs. Each unit is a pre-assembled, foldable structure that can be trucked or shipped to remote coastlines. Within 4 hours of arrival, the frame module can be unfolded to provide 5kWp to 10kWp of generation capacity. By aggregating several modules, it is possible to reach up to 100kWp.

This solar infrastructure directly powers the Aerfrigor machine’s inverter-driven compressor. By matching generation to the cooling load and utilizing the PCM “Thermal Battery” mentioned earlier, we create a truly circular energy system that requires zero diesel input during normal sunny conditions.

PER FOLDABLE UNIT

SCALABLE UP TO 100kWp+ FOR LARGE OR INDUSTRIAL CLUSTERS

AERFRIGOR • GEMPACS • MARINE COLD CHAIN PARTNERSHIP

TERIMAKASIH