A Technical Dissection of the Gempacs Solution

1. Introduction: The “Full Stack” Architecture

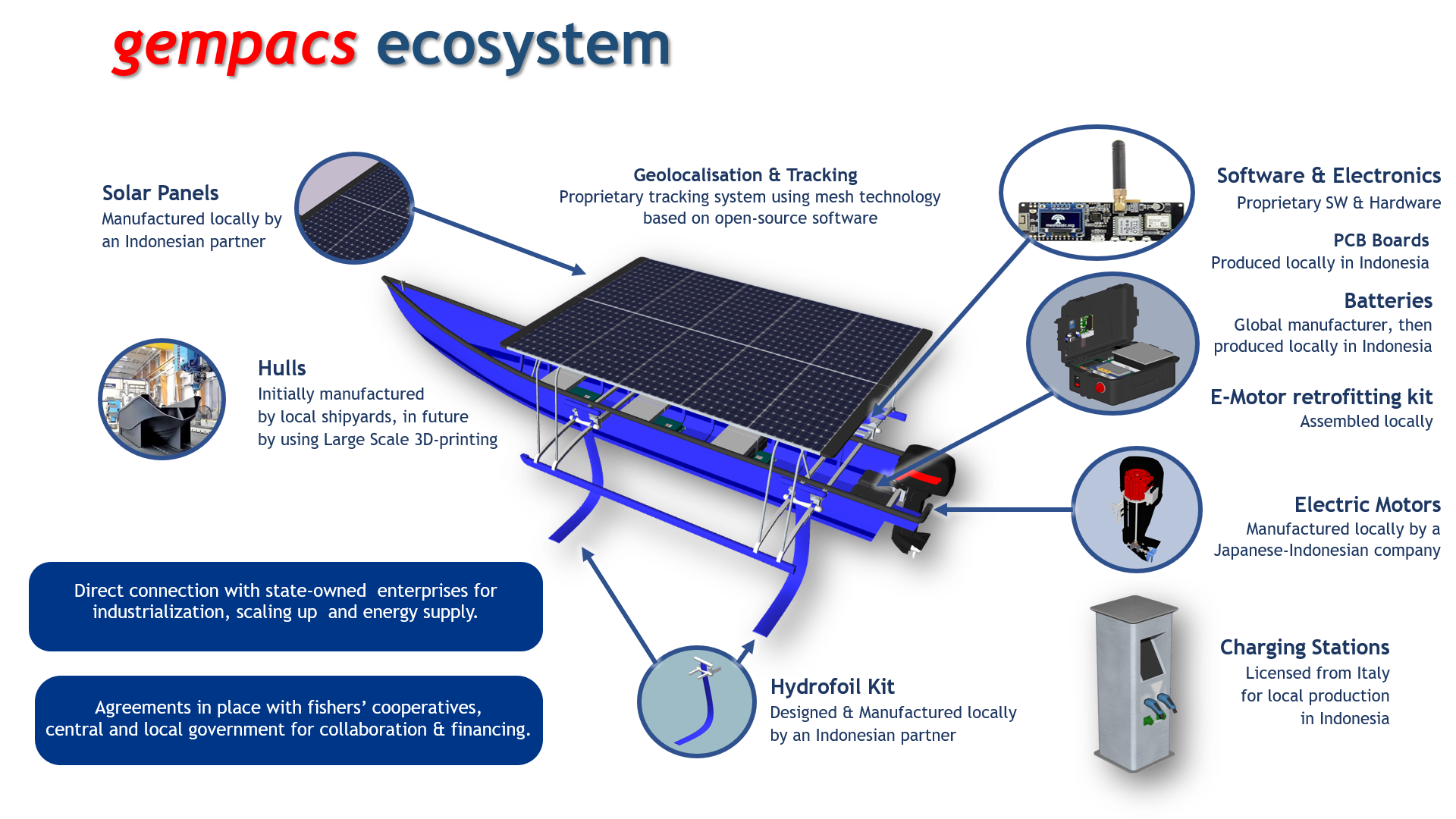

Unlike traditional marine electrification approaches that focus solely on the powertrain (motor and battery), the Gempacs solution is engineered as a “Full Stack” ecosystem. This report dissects the solution into its four constituent physiological systems: Propulsion (Muscle), Energy (Metabolism), Intelligence (Nervous System), Industrial Base (Skeleton), Financing (Food Chain).

We implement a highly modular, locally integrated architecture, designed specifically to overcome the logistical and economic constraints of the Indonesian archipelago and South East Asia.

2. The Propulsion System (The Muscle)

The kinetic core of the system is a lineup of electric outboard motors designed to match the power profiles of the internal combustion engines (ICE) currently used by artisanal fishers.

2.1 The Motor Lineup

Visual analysis of the product family (Image 1) identifies three distinct power classes, standardized to replace specific ICE “PK” (Paardekracht or Horsepower) ratings:

-

The “Coastal” Unit (3 kW / 5 PK): Designed for small canoes and near-shore operations, as well as touristic parks. This unit is available in the form factor of the small outboard engine or the ubiquitous “long-tail – ketinting” engine.

-

The “Workhorse” Unit (10 kW / 15 PK): The standard propulsion for the 8-10 meter jukung fleet. It provides the necessary torque to push loaded vessels through coastal chop. This unit is available in the form factor of the small outboard engine or the ubiquitous “long-tail – ketinting” engine.

-

The “Heavy” Unit (20 kW / 30 PK): Targeted at larger vessels, water taxis, and heavy-load fishing boats requiring higher speeds or displacement capacity.

All of these units relies on off-the-shelf mechanical spare parts, available anywhere in South East Asia.

- The “Higher Power” Units: If a bespoke project requires outboard units with much higher power (up to 200 kW – 300 HP), we can provide third party solutions, although very expensive, fully backed by our extensive know-how.

2.2 The Retrofit Philosophy

A critical anatomical feature is the Retrofit Kit. The system is not limited to new builds. The electric motor, controller, and shaft coupler are designed to be “retrofitted” into existing mechanicals and existing motor casings. This reduces the capital entry barrier by preserving the fisherman’s existing assets.

3. The Energy Matrix (The Metabolism)

The energy system is the most complex part of the anatomy, characterized by modularity and hybrid generation.

3.1 Modular Storage Architecture

The battery system is built on LiFePO4 (Lithium Iron Phosphate) chemistry, selected for its thermal stability and high cycle life in tropical climates.

-

The “Pack” Unit: The system relies on standardized 1.5 – 4 – 12 kWh battery packs.

-

Scalability: The schematic for the “Standard Boat Model” (Image 3) demonstrates a scalable architecture where a vessel can carry a minimum of 4 x 4 kWh packs (16 kWh) up to a maximum of 12 x 4 kWh packs (48 kWh), or up to 4 x 12 kWh packs (48 kWh).

-

Weight Distribution: Crucially, these packs are anatomically distributed under the seating planks along the length of the hull. This lowers the Center of Gravity (CG), enhancing the stability of the slender jukung hull—a significant improvement over top-heavy ICE engines.

3.2 The Solar “Lung”

The jukung vessel features a unique anatomical advantage: the outriggers (katir). Gempacs leverages this widely spaced structure to support a massive 3kW Flexible Solar Panel Canopy, using flexible solar panels to keep the weight low and yet a good power.

-

Function: This is not merely a trickle charger; at 3kW, the solar array can function as a primary energy source for low-speed operations (trolling), effectively allowing the boat to “breathe” energy from the environment while operating and charging the batteries in the quiet operation phases.

-

Construction: The panels are flexible, reducing weight and risk of breakage in rough seas compared to rigid glass panels, yet they use monocrystalline PERC half cells, with power yields of up to 375 Watt each.

4. The Digital Nervous System (Connectivity)

The ecosystem is bound together by a proprietary digital layer that ensures asset security and operational optimization, as well as precise carbon credits accounting.

-

- The MESH Network: A “MESH Network Radio” unit is mounted on the solar canopy. This creates a decentralized communication network where boats act as nodes, relaying data to each other. This is vital in remote archipelagos where cellular (4G/5G) coverage is spotty or non-existent offshore.

- Geolocalisation & Tracking: A MESHTASTIC LoRa module provides real-time tracking . This serves three purposes:

-

-

- Safety: Search and rescue in case of breakdown.

- Asset Security: “Geo-fencing” for investors/banks to ensure the leased asset remains in the designated operational zone.

- Carbon Credits Accounting: By knowing exactly the amount of energy consumed overtime, thus the actual savings on carbon fuels.

-

-

-

Proprietary Electronics: The system uses custom enclosures and off-the-shelf electronics, ensuring the software stack (based on open-source code) is tightly integrated with the hardware control logic by means of our proprietary software.

-

5. The Infrastructure (The Habitat)

The boat does not exist in isolation; it connects to a specialized terrestrial interface.

-

- Wall Charger (1.5 kW): A portable unit allowing slow charging from standard residential outlets or standard AC charging stations, democratizing access for fishers in remote villages without port infrastructure.

- Charging Stations: For high-throughput hubs, Gempacs deploys pedestal-style charging stations. The technology is “Licensed from Italy” but adapted for local production, bridging European tech standards with Indonesian manufacturing costs.

6. The Supply Chain (Skeleton)

Perhaps the most strategic aspect of the Gempacs anatomy is its “100% Local Supply-Chain Ecosystem” (Image 2). This is a defensive moat against currency fluctuation and supply chain shocks.

-

- Localization Layer:

- Solar Panels: Manufactured locally.

- PCBs & Electronics: Produced in Indonesia.

- Batteries: Cells from global manufacturers, but pack assembly occurs locally.

- Motors: Manufactured by a Japanese-Indonesian Joint Venture.

- Future Solutions: The roadmap includes advanced manufacturing techniques:

- Large Scale 3D-Printing: For rapid, low-cost hull production.

- Hydrofoil Kits: A planned upgrade to lift the hull out of the water, drastically reducing drag and extending the effective range of the battery packs, a critical evolution for smoother and faster rides.

- Localization Layer:

7. The Financial Anatomy (Food Chain)

To bridge the gap between high-CapEx technology (lithium batteries) and low-income users (artisanal fishers earning ~$3,000/year), Gempacs facilitates a financial layer directly into the product offering.

7.1 The “Pay-As-You-Save” Mechanism

The core of the financial framework is a “Zero Upfront Cost” model.2

-

- The Switch: Instead of purchasing the motor and battery, the fisher enters a micro-finance agreement facilitated by Gempacs.

- The Swap: The fisher swaps their daily variable fuel cost (diesel/petrol) for a fixed monthly loan repayment + low electricity cost.

- The Surplus: Because the electric running costs are 70-80% lower than fossil fuel, the total monthly cash outflow (Loan + Energy) is structured to be lower than the previous fossil fuel burn. This creates immediate disposable income.

7.2 Institutional Aggregation

Rather than assessing credit risk for individual fishers, Gempacs leverages existing social structures:

-

- Fisher Cooperatives (e.g., HNSI): Gempacs has “Agreements in place with fishers’ cooperatives” (Image 2). The cooperative acts as the aggregator, reducing customer acquisition costs and centralizing payment collection.

- State-Owned Enterprises (SOEs): Partnerships with entities like PLN (State Electricity Company) allow for on-bill financing or subsidized energy tariffs.

7.3 Digital Collateralization

The IoT Tracking System (Section 4 above) is not just a technical feature; it is a financial enabler.

-

- Bankability: Banks are typically reluctant to finance movable assets like small boats. The Gempacs tracking module converts the boat into a “Connected Asset.”

- Risk Mitigation: If payments are missed, the system allows for remote disabling or precise location recovery. This “Digital Collateral” lowers the risk profile for 3rd-party micro-finance partners.

- Carbon Monetization: The system tracks exact mileage and energy usage. This data verifies carbon emission reductions, generating Carbon Credits. These credits can be sold to subsidize the infrastructure cost or provide a secondary revenue stream for the cooperative.

8. Conclusion

The dissection of the Gempacs solution reveals a system that is biologically adapted to its environment. It does not simply transplant Western EV technology into a marine context; it utilizes the specific skeletal structure of Indonesian boats (outriggers) to maximize solar gain, employs a mesh network to overcome local connectivity gaps, and builds a supply chain rooted in the local industrial base to ensure economic viability. Furthermore, by embedding a micro-finance layer protected by digital collateral, it solves the liquidity crisis that otherwise traps artisanal fishers in fossil fuel dependence.